Product Superiority

1.High quality with best price

2.Well reputation

3.Factory with strong supply ability

4. Prompt shipment

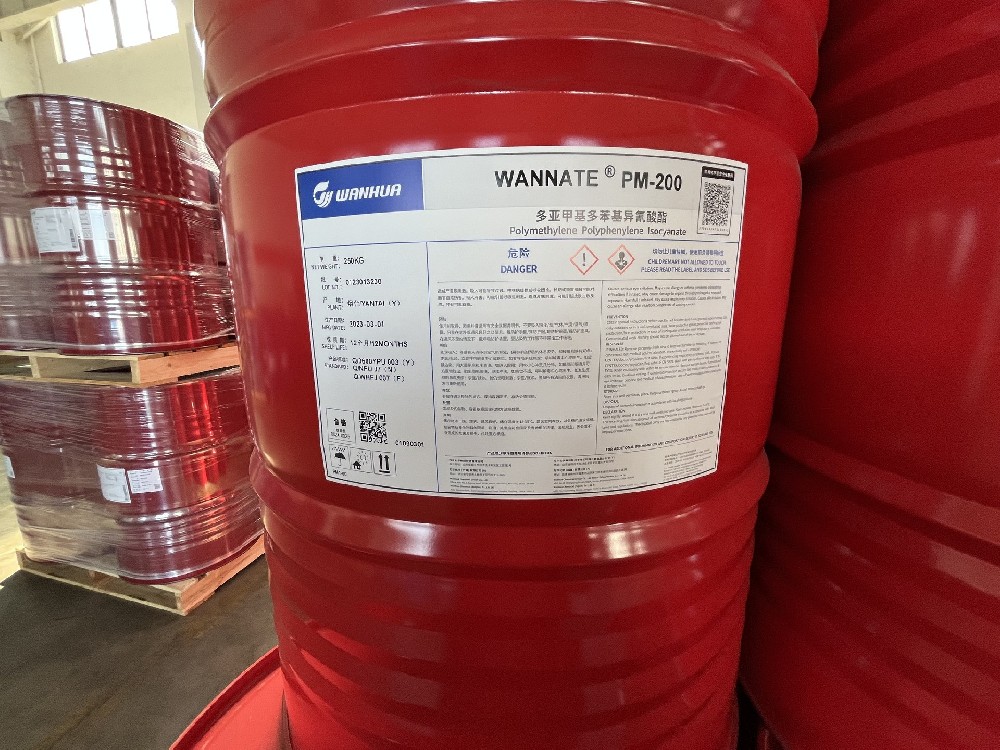

Prouct Introduction and Attributes

Polymeric MDI, generally used in manufacturing hard and semi-hard polyurethane foam. Polymeric MDI is liquefied in normal

temperature and easily handled and stored down to -20℃. It is solvent-free form with 2.7 average organic function and maximum of

125 cps (25℃) viscosity which is mixed with monomer MDI of 4,4-diphenylmethane diisocyante and its oligomer above dimer, trimer

and tetrame

Product Application

MDI is widely used in the production of PU rigid insulation foams and polyisocyanurate foams.Other uses include paints,

adhesives,sealants, structural foams, microcellular integral skin foams, automotive bumper and interior parts, high-resilience

foams and synthetic wood.

Use Method:

1. Mixing Ratio A:B=1:1 by weight

2. Component A and B should store in the temperature 15C-30C

3. Suggestion flow rate of high pressure foaming machine is >180kg/minute

Suggestion hand blender is twin-propeller , mixing speed is >2000 RPM / minute

4. If use hand blender , it must be mix A and B evently ,then pour it into mold